Rolls Service

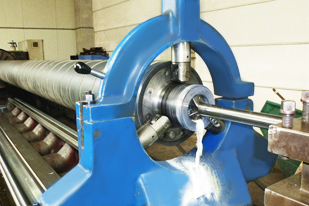

Serviceing and Maintenance

We attach the utmost importance to servicing. Our range of services therefore includes a comprehensive service offer, starting with a thorough inspection of your roll.

We offer the following services as part of an inspection:

• Balancing check

• Crack testing on pivots and shell tube

• Check of the pivot fit sizes

• Recording deviations in shape and position

• Dismantling and checking the bearing assembly

• Logging

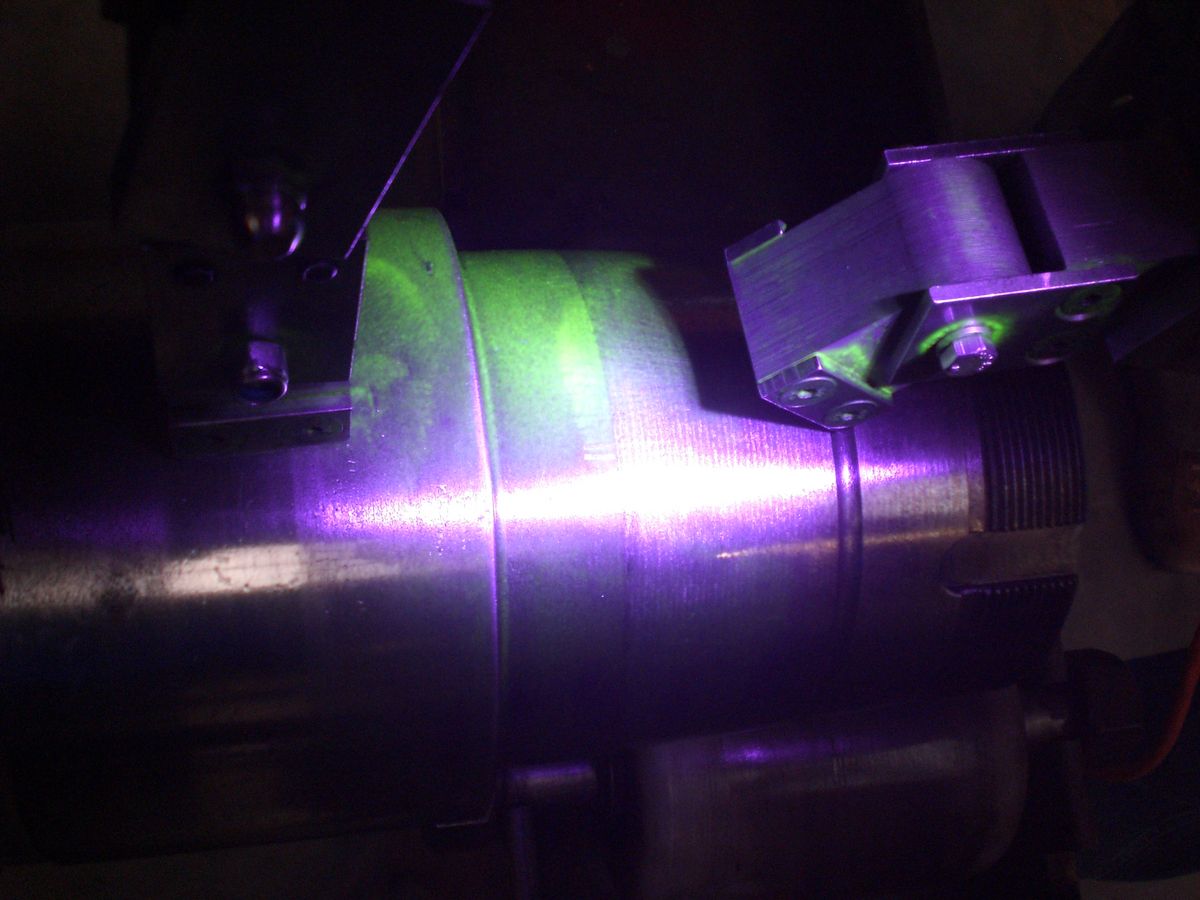

Non-Destructive Materials Testing

With our non-destructive materials testing we have created a USP on the market that sets new standards in the industry, giving our customers significant advantages. There are, however, important considerations that need to be taken into account to ensure this process can be used successfully. It is therefore imperative that the non-destructive tests are carried out professionally and in line with the latest technological developments. The tests are subject to the European standardisation.

We carry out the following tests for you:

• Magnetic particle method

• Dye penetrant test

• Phased arrays – ultrasonic testing

• Radiographic examination (X-ray)

• Visual examination of the internal body of the roll by endoscopy

Maintenance

We’ll be delighted to maintain your rolls to the highest professional standards.

The services we offer include:

• Replacement of worn pivots

• Regrinding of the roll shape – cylindrically, concavely, convexly

• Renewal and optimisation of your roll covers

• Retrofitting of a balancing system for balancing at several levels,

• Dynamic balancing as per DIN ISO 1940

• Fitting the complete bearing assembly